Denim blue knowledge you may not know

Denim blue knowledge you may not know

Denim blue is a general term for blue denim by clothing buyers and non-denim production industry personnel.

The blue of denim is mainly extra dark blue, and rarely indigo. However, under commercial demand, the colors developed on the basis of super dark blue include super dark blue + blue, super dark blue + dark, super dark blue, etc. Originally super dark blue is a color, and a good color will be very deep and dyed. The color is very transparent, but because of the cost issue, the color is graded.

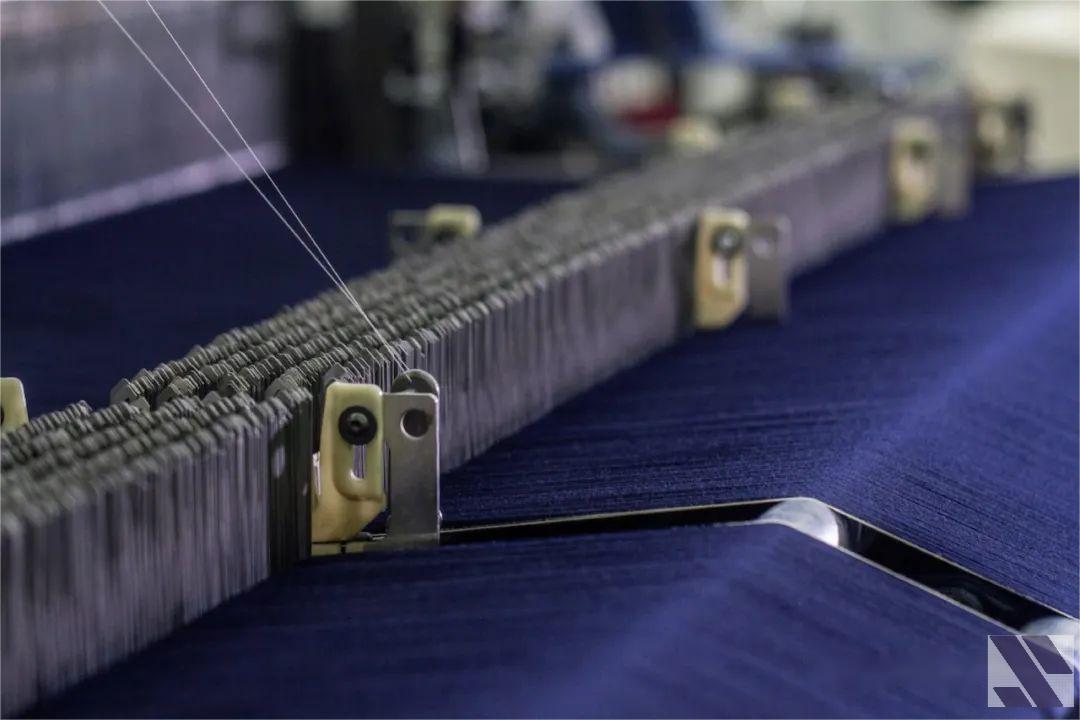

The fabric structure of jeans is woven by warp and weft, and the fabric style presents different style characteristics due to the difference in process design structure and warp and continuous density design. Before weaving the fabric, the warp yarn is selected to be 100% pure cotton, which will make the yarn better in coloring, color absorption, and color fastness. The warp of pure cotton with impurities is the opposite effect. Only good cotton yarn can be colored more easily. The yarn of chemical fiber is basically a substance refined from the petrochemical industry. Natural dyeing is the most important in denim sizing It can’t be colored, and it is easy to fade.

Then, when the warp yarn is sent to the sizing and dyeing factory, it must be dyed first. At this time, the dye is the key, because the color grading also leads to the grading of the dye, so the business rules must match, and the cheaper one is right. Use cheaper dyes, use expensive ones if they are good. Therefore, the color grade of the finished product is determined when the design target effect is set. If you want the pure color of ultra-dark blue, you must use pure undiluted dyes. In addition, the yarn must be cooked thoroughly before dyeing, the length of the dipping time must be professionally controlled in order to dye the color better, and the color will be purer, more transparent, and deeper. Under the operation of commercial interests, the dyeing operation method is further divided into sheet dyeing and rope dyeing (beam dyeing). The simple understanding is that one is less transparent and the other is more transparent. Different equipment is used for different dyeing methods. Dyeing and finishing is an independent academic field in clothing fabrics. There are many exquisite and standardized operations in technical operations and dye use. This will depend on the denim pants manufacturer positioning of product quality requirements and customer demand positioning. The dye is too good, it’s useless to think it’s too expensive. The cost of poor dyeing is low, and it is not easy to sell and is a headache. It is good to leave these problems to the fabric merchants. We only need to have a basic understanding and know how to choose fabrics. Don’t see that the fabrics provided by different suppliers seem to be similar, but the prices are completely different. It is not good to just think that others make a lot of money without understanding the inside. Basically, as a denim jeans factory, it would be nice to be able to communicate with the supplier clearly about the price and quality of the fabric I want.

How do we identify whether the color of the denim fabric is correct or not? The actual effect cannot be seen just by looking at it. Denim garment factories can see it through washing water, and washing three to four colors in deep, medium, and light. The color can change in depth, but It will not turn gray or white, that is a good color, and at the same time wipe it with white paper to see that it will not fade.

What do consumers think? When buying, look at the color of the trousers. If there are gray and white, that color is not the best color. Blue-gray is another mixed color, not the gray that was just mentioned. There is a sample at the back. From time to time, if the pants are dark in color, they won’t be noticeable. You can only wipe it with a piece of white paper or paper towel to see if the color will not fade. If there is obvious color, it is not good. If there is no problem, just look at it through wearing. After wearing it for three months, the color has changed to look better, which means that the color of the pants is very good. Because the color of the yarn dyed is very deep and transparent. If the dye is original and correct, the color will not become lighter after wearing it for a period of time but will reveal the original color of the yarn. The friction during washing and washing will make the fabric thinner in a way that is invisible to the naked eye, so the outermost yarn and color will continue to alternate between old and new. pretty. If the warp yarn of the denim is not dyed too transparent or dark enough and the color is not correct, the color will also stay on the lighter surface. Only in this way will it turn gray or white, because the color is not deep.

In fact, there is another way to check whether the color is good or not. Pinch the index finger and mother finger of the left and right hands and turn them in opposite directions at the same time. The yarn is dry. It will slowly become loose and disconnected in the middle. The looser and longer it proves that the cotton is better. At this time, if the loose yarns are colored, it proves that the dyeing is very transparent. If you see white, it is It means the dye is not deep enough.

The effect of a good super dark blue after washing is like the blue sky and sea blue, very pure and beautiful. Of course, the above is only for a basic cognition that we want the color to be very positive and deep. But what we need to know is that the cost of good color is definitely expensive, so which level of product we need should be combined with positioning and needs, only in this way can we meet the matching degree of our respective needs.

This is Amy Mok from JFY jeans company, we are denim jean manufacturer in China, and I have been in the apparel production industry for 20 years in China. If you have any questions about apparel production, including woven, knitted, denim jeans, welcome to discuss with me. I will tell you everything what I know.