In just 90 seconds, you can complete the washing process of jeans?

Jeans, almost everyone has one or two in their closet, but not many people know the production behind the jeans.

The Birth of a Pair of Jeans

Dyeing, weaving (adding white yarn to increase gloss), sewing, pre-washing process (aging, polishing), washing and other processes.

However, the production process uses thousands of chemicals (many of which are harmful to the human body), consumes and pollutes large amounts of water, and hours of processing time.

We refuse to accept the fact that “wearing jeans is polluting the environment”, but you have to admit that the cheaper the jeans are, the less environmental protection measures are in the production process. Compared with the excessive waste caused by chasing luxury goods, the excessive consumption of low-consumption groups on shoddy fast fashion brands is particularly obvious.

While you are pursuing the distressing and washing process of jeans, your and my endless pursuit of materials is the biggest source of environmental pollution.

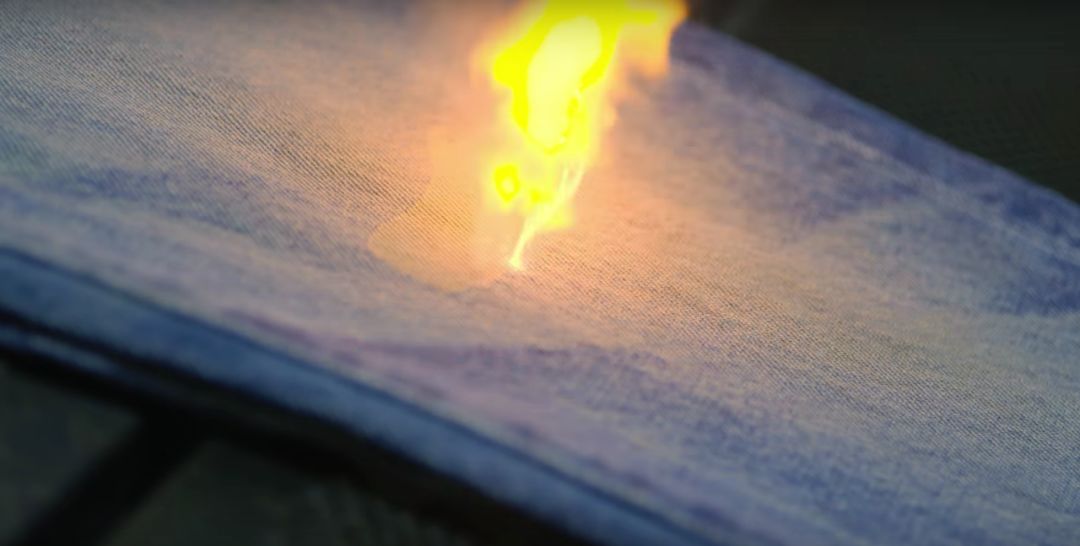

In order to reduce the pollution caused by the production of jeans, the American jeans giant Levi’s recently officially released a new laser polishing technology called PROJECT F.L.X. – using lasers to make various wear effects on jeans.

In the past, workers had to spend hours in front of a pair of jeans, only to create different distressing and wear processes by hand, and then throw the jeans into a large washing machine for aging. The latest Levi’s PROJECT F.L.X. replaces all manual old-fashioned processes with lasers.

In the past, using human hands to make different wear effects required workers to do a lot of repetitive work, and we had to use thousands of chemical substances, but with the new technology, we only need to use dozens of chemical substances. For us, this is already a big victory.

Even better, from now on, the designer can design the old-fashioned effect of the jeans on the supporting software, and use the laser machine to achieve a more accurate effect. In the past, when the designer drew the desired effect, the factory would make prototypes more in the form of groping, which also means that failed attempts may bring waste.

Levi’s said that for a company whose production lines are distributed around the world, the entire process from prototype to mass production will take more than a year. Now with this new technology, it only takes a few hours from design to prototype, and even to mass production, it only takes a few months to complete.

We look forward to more black technologies in the future to help companies achieve sustainable fashion development.

This is Amy Mok from JFY jeans company, we are a denim jean manufacturer in China, and I have been in the apparel production industry for 20 years in China. If you have any questions about apparel production, including woven, knitted, denim jeans, welcome to discuss with me. I will tell you everything that I know.