When talking about jeans, people will naturally think of the gold rush in theUnited States in 1849. At that time, the first batch of immigrants who set foot on the American mainland, can be said to be poor and white, and they had to work hard. Intense labor makes clothes easy to wear and tear, especially in 1849 when miners swarmed into California, forming the famous gold rush at that time. Because the clothing material is very easy to break, people are eager to have a kind of durable clothes. Against this background, strong and durable jeans arise at a historic moment. Levi Strauss is recognized as the inventor of jeans. In 1850, the 501 jeans produced by Levi`s, which he founded, are the originator of jeans known to the world. In the mid-1930s, jeans, which were worn by almost everyone in the agricultural belt of the Midwest of the United States, were brought to the bustling cities east of the Mississippi River for the first time. Since then, jeans have entered the ranks of popular clothing.

Washing denim is an important process in jeans making. Its function is, on the one hand, it can make the denim softer and easier to wear; on the other hand, it can beautify the jeans, such as whiskers, blasting, snow washing, etc. Pants are different from casual pants. The fabric of jeans can only be worn after washing. There is a layer of slurry on the raw denim. If it is not washed, the denim will be very hard and uncomfortable to wear, and it will also have a bad effect on the body.

Rinse washing is ordinary washing, it’s similar we are familiar with washing, but use a bigger industrial washing machine, the water temperature is about 60°-90°C, add some detergent, usually, it washes 15-30minutes, rinse with clean water and soften, It can make the fabric softer, more comfortable, more natural and cleaner visually.

Generally, according to the length of washing time and the number of chemicals used, general washing can be divided into light washing, medium washing, and heavy washing. Usually, the light washing is about 5 minutes, the medium washing is about 15 minutes, and the heavy washing is about 30 minutes (this time is not precise), there is no obvious boundary between these three washing methods.

Stone washing is adding a certain size of pumice stone to the washing water to polish the pumice stone and the Jeans. The water level in the polishing tank is carried out at a low water level at which the clothes are completely soaked so that the pumice stone can be in good contact with the clothes. General washing or rinsing can be carried out before stone grinding, and rinsing can also be carried out after stone grinding. According to the different requirements of customers, yellow stone, white stone, AAA stone, artificial stone, rubber ball, etc. can be used for washing to achieve different washing effects. After washing, the cloth surface will appear gray and old, and the jeans will be slight too severely damaged, creating vintage denim jeans.

Enzymes, can be used to degrade the cellulose in cotton fibers. Since the color of denim is actually attached to the outer layer of the yarn, after enzyme washing, the fiber and the indigo dye attached to it can be washed off together. When the desired color is obtained, the enzyme wash can be stopped by changing the alkalinity of the water or raising the water temperature. Then proceed to the next step of rinsing and softening. Enzyme washing is gentler than stone washing because no sharp stones are used in the enzyme washing process. Enzyme-washed denim has uniform color and soft handle, suitable for home textiles and clothing. Different wash times and the addition of different amounts of chemicals can create a variety of shades of jeans, the color from light blue, to medium to dark blue denim.

In the denim finishing process, pumice and enzymes are used together to give denim a vintage jeans effect. In the first step, only the pumice stone and fabric are put into the washing tank, and then the enzyme is put into it in the next step, the pumice stone and fabric are tumbled together until a natural nostalgic effect is produced. This wash is most commonly used with blue denim.

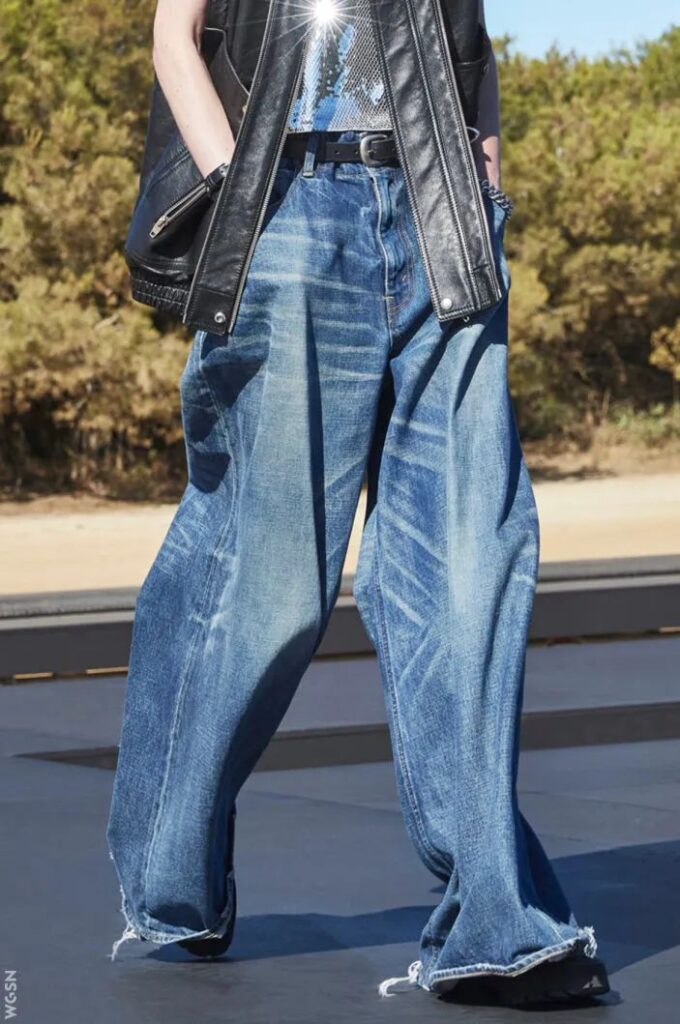

This finishing uses a row of horizontal rollers, which can be covered with sandpaper or chemically treated abrasives. The denim is slipped over the rollers and the raised areas are sanded. This finishing method partially fades the denim and creates a fleece on the denim surface, giving it a soft, delicate hand. The sand washing method can also produce fashionable appearance effects such as crinkle and cat whiskers on denim.

In order to make the clothes have a white or bright appearance and a soft feel, the clothes need to be rinsed, that is, after ordinary washing, the temperature is raised to about 60°C, and an appropriate amount of bleaching water (sodium hypochlorite solution) is added to rinse according to the bleaching color. A certain amount of time, and consistent on the board. After the bleaching of the clothes is completed, Hypo is added to neutralize the residual chlorine in the water, and the bleaching is completely stopped. After clearing the water, add detergent, fluorescent whitening agent, hydrogen peroxide, etc. to the water temperature of 50°C for final washing to neutralize the pH value while fluorescent whitening, etc., and finally soften it. It should be noted that during operation, the direction of adding bleach should be consistent with the direction of the rotary cylinder, so as not to dilute the bleach. Rinsing can be divided into itching bleaching and chlorine bleaching. Oxygen bleaching uses hydrogen peroxide to bleach, and the surface of the bleached cloth will generally turn slightly red. Chlorine bleaching is sodium hypochlorite bleaching. The fading effect of chlorine bleaching is rough, and it is suitable for rinsing indigo denim.

Jeans are often over-dyed, and the commonly used dyes are vat, vulcanized, reactive, and direct. The dyeing of votive fuel and sulfur dyes cannot be dyed by industrial washing machines, but can only be carried out in specific dyeing vats, which requires a certain degree of difficulty in operation, so it is rarely used at present; dyeing of reactive dyes mostly uses low-temperature dyes for one-bath dyeing, but it must be fully Wash to neutral and dry in time to avoid defects such as seals; at present, direct dyeing is generally used for middle and low-end clothing. The process is relatively simple, but the color fastness is not good.

Also known as stone grinding, it uses a special frying machine, which is like a water washing machine without a shell and only uses a rotating cage. The principle is to put the pumice stone in the frying machine, pour diluted floating water (sodium hypochlorite solution), rotate it to make the pumice stone absorb evenly, and then put it into the denim clothing for rotation, through the mutual friction between the pumice stone, clothing, and machine wall, Partially wear off the dye on the surface of the clothing, and at the same time, the ash produced by the pumice is stained on the surface of the clothing. The floating water contained in the ash will destroy the indigo or sulfur dye on the clothing through oxidation, and play a certain role in stripping and bleaching.

It is also called snowflake, which is similar to dry grinding, and it is also carried out by a frying machine. Compared with dry grinding, the whiteness is whiter, and the flower degree contrast is larger, but it is not as uniform as dry grinding blue grinding. The white grinding of clothing is like a large snowflake. Covered with clothes and fried in the name of snowflakes. The principle is to soak the dry clothes with potassium permanganate solution, and then directly polish the clothes in the rotary cylinder of a special frying machine, and eliminate part of the indigo pigment through the strong oxidation of the potassium permanganate solution emitted from the pumice. In addition, the potassium permanganate solution infiltrates into the clothing with the help of pumice and its ash powder as a medium and forms white spots similar to snowflakes through strong oxidation.

Use an electric brush or grinding wheel to directly polish the surface of the fabric, so that the surface of the clothing can achieve a partial whitening effect, suitable for large areas such as front legs, knees, and rear buttocks. This process generally uses a trouser-blowing machine (such as a vertical trouser grinder) to inflate and fix the trousers with an inflatable model “glue wave”. Then use electric equipment to polish, and finally manually trim small parts such as the edge of the trouser seam, the edge of the pocket, and the hem of the trouser leg, in order to achieve a special effect.

Also called hand sanding, it is relative to machine wiping. Common methods include hand brushing, sandpaper wiping, and knife wiping. Later, it deviates from the original intention. It is a general term for many small crafts. For example, ordinary cat whiskers are a kind of hand wiping. , it is just ground into the shape of whiskers through mechanical equipment. Hand rubbing generally refers to the process of physically damaging and fading denim fibers on the surface of clothing with tools such as sandpaper, blades, and small grinders.

It is obtained by processing the effect like a cat’s whiskers. The other reason here is that there are many kinds of crafts in this part. It can be obtained by grinding and washing after sewing, or by rubbing a horse after sewing or directly grinding it out with a grinding wheel. There are various theories, but there is no standard. Recently, it is obtained by rubbing a monkey after the three-dimensional creasing of resin. It is called three-dimensional cat whiskers, and there are flat cat whiskers and round cat whiskers.

As mentioned in the previous paragraph, the principle is the same as iron-free finishing. The purpose is to form long-lasting specific wrinkles according to the processing requirements. It is combined with grinding and washing monkeys, sandblasting, hand rubbing, and other processes to express the style. The operation process can refer to the three-dimensional cat whisker process. The requirements for the process mainly include: three-dimensional shape retention; good strength retention; no monkey macula; formaldehyde residues that can meet the requirements of national standards; the background color should not be flooded as much as possible.

Also known as sanding, it uses compressed air as the power, sprays emery at high speed with a special nozzle to the surface of jeans, and uses the grinding effect of emery to form the effect of wear and fading on the surface of clothing. Corundum can be recycled and then added to the sand cylinder for continued use. The working environment of sandblasting is relatively harsh, and operators need a full set of dust-proof equipment.

It is similar to sandblasting in effect, but the former relies on chemical reactions, while the latter relies on physical damage. Monkey spraying is to using a spray gun to spray monkey water (a mixed solution of potassium permanganate and phosphoric acid) onto clothing according to the design requirements, and sometimes use templates to achieve more refined artistic patterns. The oxidation of the monkey water will destroy the indigo dye or high-quality sulfur dye on the surface of the denim, the color of the dye will be faded, and the potassium permanganate will reflect the product manganese dioxide (brown/orange) through subsequent reducing agents such as oxalic acid and hydrogen sulfite. Sodium and other water are removed by washing, and the surface of Ma Liushui clothing will have a frosty white effect, which is called Ma Liushui. The degree of fading frost-white effect is controlled by the concentration and spray volume of the monkey. Compared with the fading of hand rubbing and sandblasting, the fading of monkey is more uniform and stronger, and basically has no physical damage to clothing.

To form trademarks or patterns on jeans, the initial method is to paste and seal the cut patterns on the trousers, and then tear off the patterns after washing. At this time, the jeans will naturally have unwashed pattern outlines. There are also designers who directly engrave various flower patterns on jeans. Now, the blue floating on the surface of the yarn can be easily removed with a laser machine, special patterns can be carved on the fabric, and various patterns with hollow effects can also be cut on the surface of the fabric, making the finished product more refined and creative.

Also known as “ice crack”, strictly speaking, it should belong to the category of monkeys, but at present, this craft will have a trend of a popular development in the market, so it is specially listed and discussed. The core of this craft lies in the use of “explosive pulp” and the production method It is to scrape and coat the bursting material on the surface of denim clothing with a certain thickness by hand, and then dry the clothing (usually in an oven). After drying, the bursting slurry on the surface of the clothing will form various natural cracks, and then spray the clothing Monkey, monkey penetrates into the cracks and reacts with clothing dyes, and then washes to remove the slurry and restores and neutralizes. The surface of the clothing presents white lines consistent with the cracks, which are called burst cracks or ice cracks.

Thanks for reading! This is Amy Mok from JFY jeans, I have been in the apparel production industry for 20 years. If you have any questions about apparel, including woven, knitted, or denim jeans, welcome to discuss with me. I will tell you everything I know.